Murray Leinster’s short story Things Pass By, published in 1945, includes what may be the first description of 3D printers:

But this constructor is both efficient and flexible. I feed magnetronic plastics – the stuff they make houses and ships of nowadays – into this moving arm. It makes drawings in the air following drawings it scans with photo-cells. But plastic comes out of the end of the drawing arm and hardens as it comes … following drawings only.

Practical 3D printers, or additive manufacturing as it is also known, have been around since the 1980s. After some theoretical experiments, American Bill Masters developed and patented several techniques that laid the foundation for the first commercial 3D printers. 40 years later, 3D printers have become so cheap and easy to use that anyone who is interested can get one.

Rapid development

For a long time, the technology was only used as a way to quickly create prototypes before a final design was produced in a more mature and cheaper process such as injection moulding. For a long time, it was also only possible to print 3D objects in various plastic materials, but in recent years both the applications and the materials have broadened.

“What I have seen is that 3D printers have come a long way in recent years. Both the hardware and the software have improved, but more importantly the ecosystem has matured. Printers can now handle many different materials – from pla (a kind of polyester) and resin to steel, kevlar, and even organic materials. After over 25 years of development, I have seen a real boom in the last 2-3 years, especially with more accessible and user-friendly software. There is now an evolution where 3D printers are spreading from specialists to wider use in industry and among consumers,” says Chris Fotheringham, a game developer and entrepreneur who is just starting a new company combining 3D printers and AI.

Brian Loudon

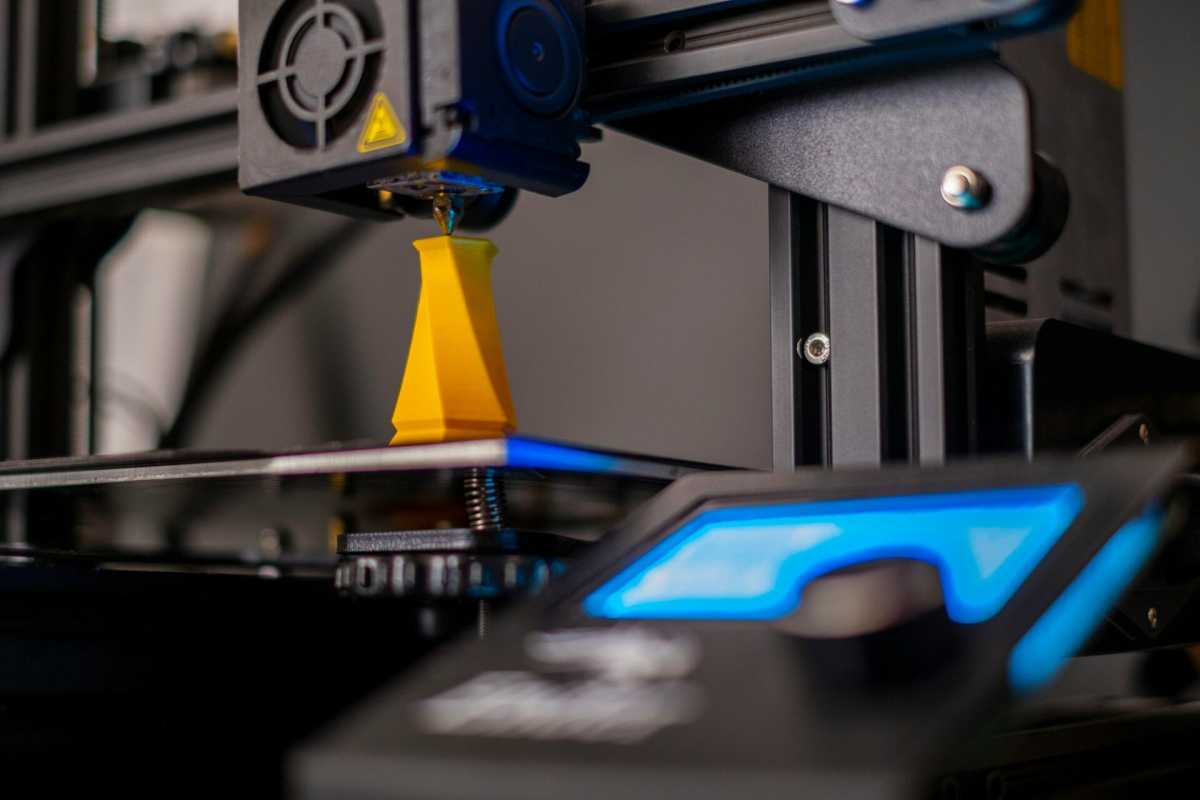

Brian Loudon, a design consultant based in Glasgow, says even old tried-and-tested techniques have evolved a lot in recent years. This is particularly true of filament printers, also known as FDM or FFF (as in Fused Filament Fabrication) – the type of 3D printer most people are familiar with, which is fed with long strands of, for example, ABS plastic.

“After a key patent on FDM expired in 2009, there was an explosion of low-cost consumer printers that made it possible to use 3D printers in various hobbies. The big price cuts also helped small design and engineering studios like mine. In this market, China’s Bambu Labs has made a massive and rapid impact with new printers that take 3D technology to the max. They have achieved several times faster printing with techniques that utilize printer vibrations and more, with clean prints despite the high speeds.”

“What used to take a whole working day can now be done in an hour”, says Brian Loudon. Now he can have an idea in the morning, produce a cad model and have an early prototype by the afternoon.

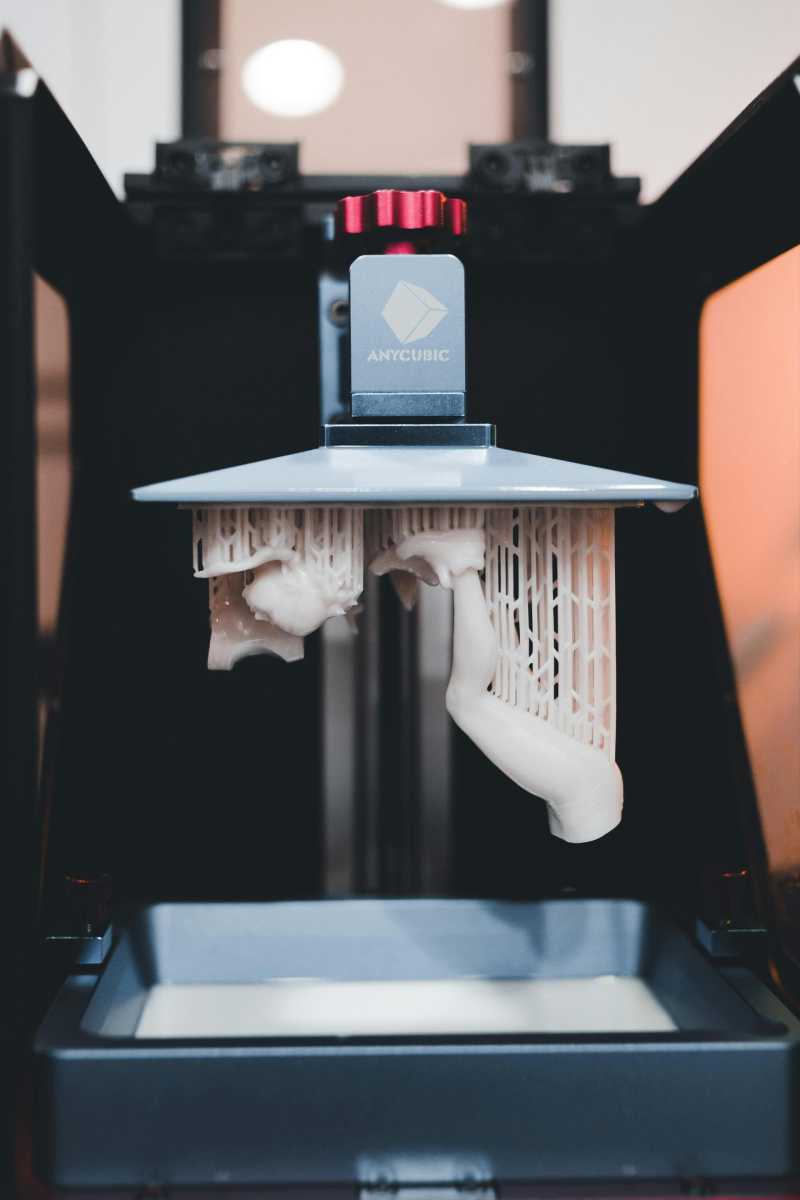

Resin-based printers, which use liquid polymer, have also become significantly faster.

New materials open up new possibilities

Like Chris Fotheringham, Brian Loudon points to the many new materials that can be used with modern 3D printers as an important part of the development, giving as an example the company Markforged, which makes a filament with carbon fiber. This makes it possible to print fittings and other components that need high strength and heat resistance.

Metal has come on strong in recent years as a material used for additive manufacturing. Researchers at Chalmers University of Technology in Gothenburg, for example, have made great strides towards materials that can achieve similar properties to casting or forging.

Concrete is another example. Several companies around the world today manufacture various buildings on site using huge 3D printers that build houses in layers. A Japanese manufacturer recently developed yet another technology that blends state-of-the-art with techniques thousands of years old. Lib Work uses soil, lime, and natural fibers and its buildings have achieved the highest level of earthquake safety.

In 2024, the University of Maine unveiled the world’s largest 3D printer, which can print objects up to 29 meters long. Called Factory of the Future 1.0, it’s intended to be used mainly to make house parts for renovations of historic buildings. With up to 227 kilograms printed per hour or over five tons per day, it’s no mean feat.

Mikael Wallerstedt

Can create previously impossible structures

Cecilia Persson, professor at Uppsala University, discusses another exciting consequence of developments in additive manufacturing: the possibility of creating shapes and structures that have not been possible before.

Can 3D printers do something that has never been possible before?

“Yes, they can! I usually give two examples, one in component manufacturing and one in materials. You can optimize structures, for example, to minimize material use but get the same strength, for durability for example, including saving fuel with lighter components. In other words, you have a completely different kind of design freedom. Then you can develop materials with other microstructures, for example gradients of different microstructures within the same material as well as amorphous materials like metallic glass. Metal glass has traditionally been made only as thin films or wires, but now you could make larger, more complex parts.”

Brian Loudon also talks about how 3D printers enable lighter components by optimizing the three-dimensional structure such as for extremely efficient heat exchangers that could not be made using traditional methods such as CNC machines or injection molding.

Making a big difference in medical technology

Cecilia Persson’s research focuses on how additive manufacturing can be used in medical technology.

“3D printers are mainly used for three different things: anatomical models to practice and/or explain surgical procedures, surgical guides – that is, patient-specific aids to surgery – and patient-specific implants and/or implants with specific properties that cannot be achieved with other manufacturing methods, or are much easier with 3D printers. Examples of patient-specific implants so far come mainly from skull and jaw surgery.

She points to an article in the 2023 issue of Tandläkartidningen that shows how 3D printers are already being used to rebuild damaged jawbones, allowing patients to receive dental implants that would otherwise not have been able to be attached anywhere. (*Beware of graphic images of surgical procedures.)

One area Persson is currently researching is the development of degradable materials for temporary implants, such as replacement bones that break down as the body’s own bones grow back.

Brian Loudon

Brian Loudon also works with clients developing medical devices of various kinds. He often uses 3D printers in combination with 3D scanners to produce, for example, different types of supports that fit a patient’s body exactly.

He explains, “I have also used 3D printers that handle more than one material at a time to develop new supports for patients with arthritis with the National Centre for Prosthetics and Orthotics in Glasgow. The finished product will be injection molded with a rigid core and soft exterior, and multi-material printers have allowed prototypes of the same design to be produced and tested.”

Customized design and flexible manufacturing

Brian Loudon has been working with 3D printers for prototyping and design development for over ten years. For him, the benefits of being able to go from an idea to a physical prototype more or less instantly are obvious, but he also sees the technology being used more and more to make the final products.

“That’s one of the big changes we’re starting to see. Maybe not quite on the scale required for mass production yet, but both Adidas and Nike, for example, have started making midsoles with 3D printers and in Formula 1 McLaren uses 3D printed components in their cars. An interesting trend that has now been supported by a major consumer brand is the printing of spare parts. Philips has introduced Philips Fixables with Prusa Research to encourage users to repair instead of discarding gadgets when any part breaks.

Chris Fotheringham believes that the ability to produce unique, customized designs will drive huge growth on the consumer side as consumers will be able to solve problems and realize their ideas themselves. He cites the example of how 3D printers are being used in the hobby of cosplay to produce costume parts with incredible detail.

In various hobbies, 3D printers have long since changed what is possible for individuals to do themselves, and also what role manufacturers play. This is especially true for miniature games and model railways. 3D printers make it possible to print spare parts and components that manufacturers have never sold separately. Users can also design and print completely new components and accessories. Where in the past many people built landscapes by hand using materials such as cardboard, Styrofoam, and cellular panels, today the use of 3D printers has become commonplace.

Privat

“On the industrial side, the potential is even greater. I see 3D printers as a way to localize manufacturing again. Countries will be able to manufacture exactly what they need at home. Look, for example, at how Ukraine has used 3D printers in its own defense,” says Fotheringham.

His new company is developing AI-based software that turns two-dimensional images into 3D models that users can then print without any prior knowledge. In the image opposite, you can see an example of a dog figure that Chris Fotheringham has made to test and showcase the software.

Chris Fotheringham

“One of our long-term goals is to create a catalog of printable household products, to help people return to a culture of repair.”

This articles is written by : Nermeen Nabil Khear Abdelmalak

All rights reserved to : USAGOLDMIES . www.usagoldmines.com

You can Enjoy surfing our website categories and read more content in many fields you may like .

Why USAGoldMines ?

USAGoldMines is a comprehensive website offering the latest in financial, crypto, and technical news. With specialized sections for each category, it provides readers with up-to-date market insights, investment trends, and technological advancements, making it a valuable resource for investors and enthusiasts in the fast-paced financial world.