While you tend to think of diamonds as ornamental gemstones, diamonds also have many important industrial uses, and many of those diamonds are now synthetic polycrystalline diamonds. How are they made? [JerryRigEverything] takes us behind the scenes at a diamond manufacturing facility, something you don’t get to see every day. Check out the giant presses that exert about a million pounds of pressure in the video below.

The process starts with diamond powder, which is just what it sounds like. Although you can get real diamond powder, most uses today start with synthetic diamonds. The powder has many uses in cosmetics and as an abrasive. But the video will combine it with cobalt and table salt to form diamond shapes.

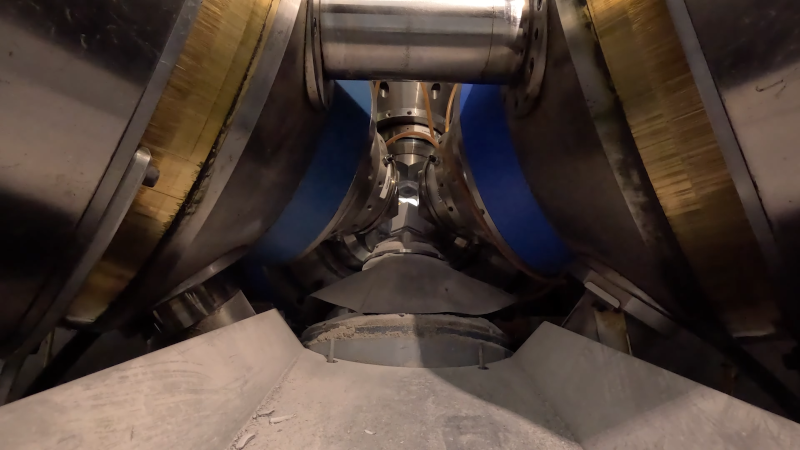

The salt is a high-temperature electrode. The process requires temperatures of nearly 1400C (2500F) and a lot of pressure. Common talc, some metal electrodes, and a heater tube are also used in the process.

The press can convert a little diamond dust into a diamond in about 10 minutes. However, because the machines are so dangerous, they are each set in their own blast room, which is sealed when the press is in operation.

While this press was — no pun intended — impressive, we’ve seen bigger. Nothing like this will show up in your garage anytime soon, although, as the video shows, you can buy 3D printer nozzles made from the material. As for a press, you might have to just settle for an arbor press.

This articles is written by : Nermeen Nabil Khear Abdelmalak

All rights reserved to : USAGOLDMIES . www.usagoldmines.com

You can Enjoy surfing our website categories and read more content in many fields you may like .

Why USAGoldMines ?

USAGoldMines is a comprehensive website offering the latest in financial, crypto, and technical news. With specialized sections for each category, it provides readers with up-to-date market insights, investment trends, and technological advancements, making it a valuable resource for investors and enthusiasts in the fast-paced financial world.