- Researchers at Imec have found a way to grow lasers directly on silicon

- Imec’s lasers use gallium arsenide, a material that doesn’t naturally bond with silicon

- This breakthrough could lower costs and improve photonic chips for AI and telecom

Silicon photonics uses light to transmit data instead of relying on electrical signals, but since silicon itself can’t efficiently generate light, it requires lasers as a light source.

Placing lasers onto chips has traditionally been a challenge as Silicon – a material commonly found in sand – is not suitable for making lasers, and the best laser materials, such as gallium arsenide (GaAs), do not naturally work with it. Existing methods require bonding these materials onto silicon, a process that’s both costly and wasteful.

Scientists at Belgium research center Imec, have come up with a solution to this problem which involves growing lasers directly on silicon. This discovery could lead to more affordable and scalable photonic devices, potentially transforming applications in data communication, machine learning, and AI.

Short wavelengths

Imec’s approach, detailed in a paper published in Nature, builds on nano-ridge engineering, which confines defects which would otherwise degrade laser performance.

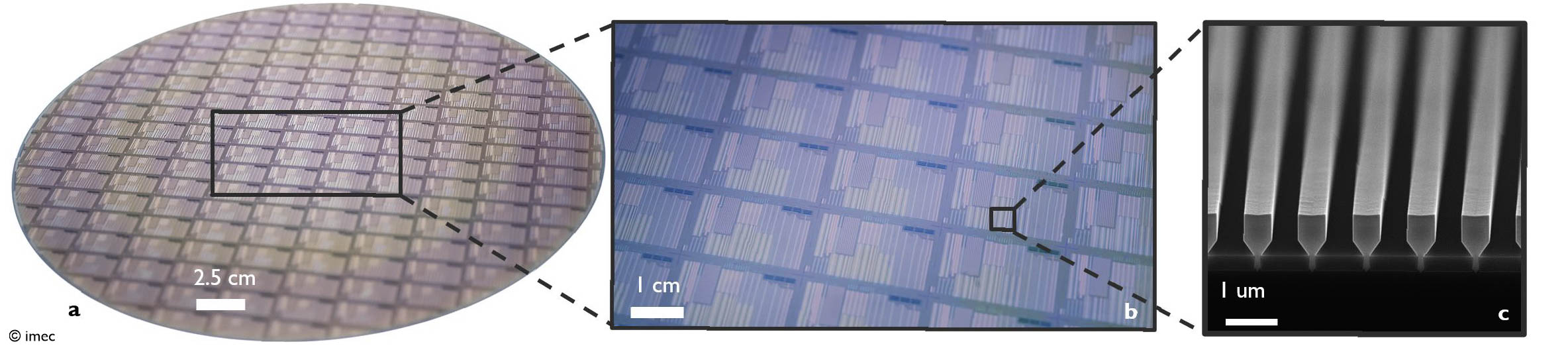

They begin by covering a silicon wafer with a layer of silicon dioxide and etching in arrowhead-shaped trenches (“like a field plowed prior to planting” as IEEE Spectrum describes it). Gallium arsenide is then deposited into these trenches, where it only makes contact with silicon at the bottom. This placement keeps any defects buried within the trench and prevents them from spreading into the laser material above.

The lasers use indium gallium arsenide (InGaAs) multiple quantum wells as the optical gain region and are embedded in a doped p-i-n diode structure. They operate at room temperature with continuous-wave electrical injection, achieving threshold currents as low as 5 mA and output powers of up to 1.75 mW.

“Over the past years, Imec has pioneered nano-ridge engineering, a technique that builds on SAG [selective-area growth] and ART [aspect-ratio trapping] to grow low-defectivity III-V nano-ridges outside the trenches,” said Bernardette Kunert, scientific director at Imec.

“Now, Imec exploited the III-V nano-ridge engineering concept to demonstrate the first full wafer-scale fabrication of electrically pumped GaAs-based lasers on standard 300 mm silicon wafers, entirely within a CMOS pilot manufacturing line.”

The nanoridge lasers emit light at 1,020 nanometers, which IEEE Spectrum points out, is a shorter wavelength than those typically used in telecommunications. Imec’s researchers say they are actively working to extend the wavelength and improve the design to reduce defects near electrical contacts. If successful, this approach could provide a scalable and cost-effective solution for integrating lasers into silicon photonics, paving the way for the high-performance optical devices of the future.

You might also like

This articles is written by : Nermeen Nabil Khear Abdelmalak

All rights reserved to : USAGOLDMIES . www.usagoldmines.com

You can Enjoy surfing our website categories and read more content in many fields you may like .

Why USAGoldMines ?

USAGoldMines is a comprehensive website offering the latest in financial, crypto, and technical news. With specialized sections for each category, it provides readers with up-to-date market insights, investment trends, and technological advancements, making it a valuable resource for investors and enthusiasts in the fast-paced financial world.