The place did the thought for DeepReview come from?

Romain: The idea got here from a collaboration with a buyer who shared some AOI pictures and corresponding certifications with us. On the time, I used to be on the Heart for Deep Studying in Electronics Manufacturing (CDLe), a five-year joint business initiative in San Jose, California. I used to be surrounded by among the greatest consultants within the area, and we needed to see what sort of buyer worth may very well be generated by making use of deep studying to the huge quantities of high-quality inspection information that every one our clients are sitting on. Since picture classification is among the most mature purposes inside deep studying, it didn’t take lengthy to construct a superb neural community.

So, was this a mannequin that may very well be utilized immediately in manufacturing?

Romain: Perhaps for this buyer, but it surely wouldn’t have labored for anybody else. There are such a lot of variables just like the design, colour and kind of part, which all complicate classification. Even between clients, tolerances differ. Some would wish to restore a selected difficulty. Others wouldn’t. And that is the core problem: A generic mannequin is extraordinarily troublesome to create. Each buyer has their very own requirements, their very own provide chain and course of variations, and solely they’re utterly accustomed to what high quality requirements are acceptable.

Romain Roux R&D Director for AI, Mycronic (left).

Nicolas Guillot Software program Techniques Architect, Mycronic (proper).

Have you ever met customers who’ve tried to develop their very own AI classification programs? If each neural community must be custom-made, why don’t they simply construct their very own from scratch?

Romain: Positive, there are customary algorithms on the market. However the ramp-up is daunting. It’s important to develop the instrument, label the info, discover ways to use the library, hook up with the AOI system, and so on. It might simply be a half-million-dollar challenge, and even then you definately’d must be a knowledge scientist to make use of it. As a substitute, we’ve constructed the mind and an interface that speaks inspection language, fairly than specialised picture processing language. So clients can simply perform a little labeling, which they already do when reviewing AOI defects, and deal with what they’re greatest at: stopping actual defects.

Nicolas: That is actually the important thing level. Our clients have already got every little thing they should use DeepReview. They’ve acquired years of precise manufacturing information. They’re already labeling, classifying and performing sanctions on false calls and true defects. We’ve targeted our efforts on constructing a deep studying system that learns from what they’re already doing, so an individual doesn’t preserve having to do the repetitive jobs {that a} machine can do. They shouldn’t must babysit a machine and continuously sanction false calls, they usually undoubtedly shouldn’t want a PhD in picture processing or AI. They need to be on the market kitting, dekitting and doing restore, the place their experience is required most!

So, what sort of time financial savings are we speaking about? What number of false calls can clients count on to chop out of their every day work?

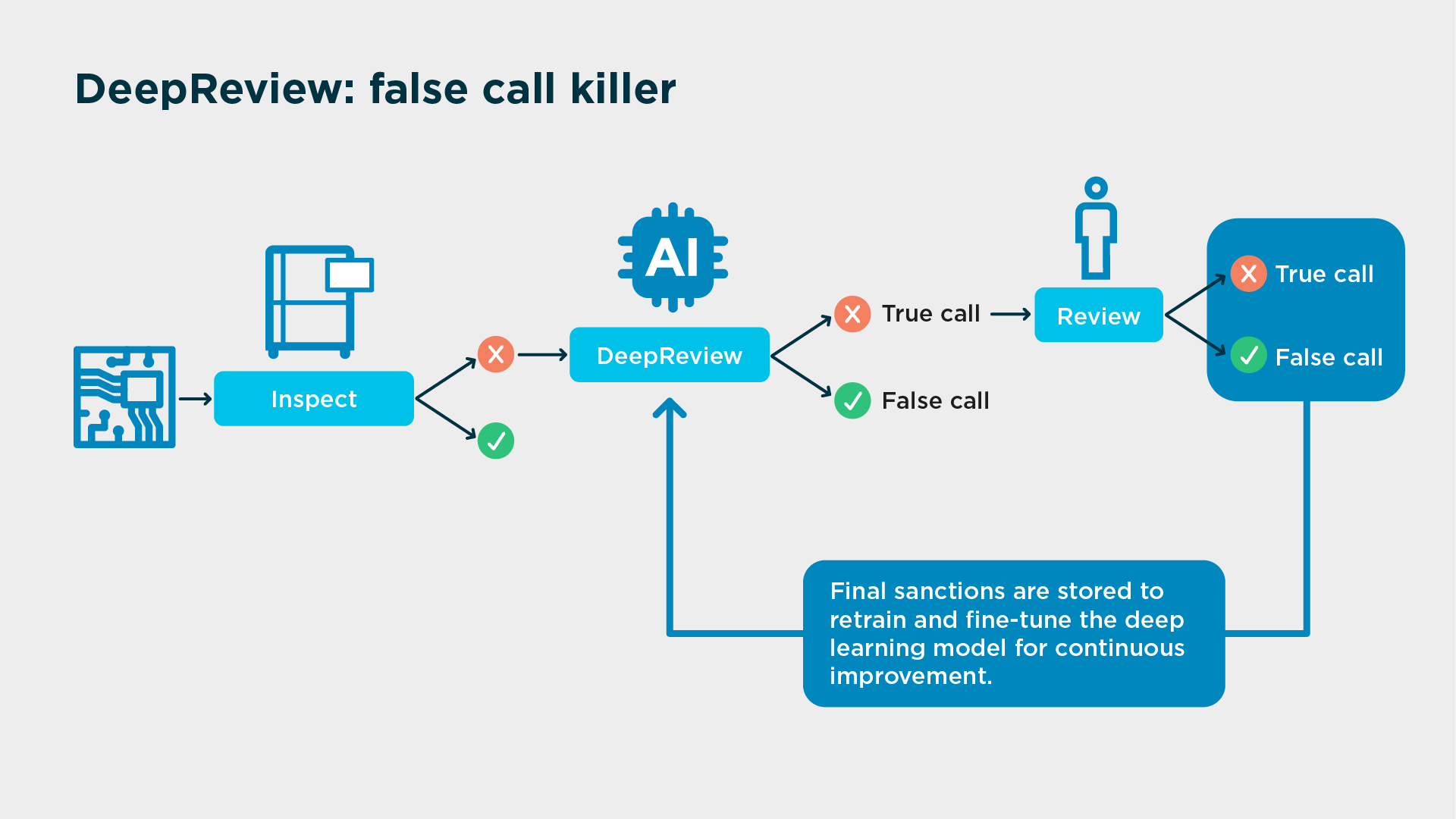

Nicolas: It actually is dependent upon the variability and kinds of elements, however 50-90% fewer false calls is a sensible expectation. With DeepReview, an operator can undoubtedly really feel assured that they’re extra pro-ductive, with much less threat for errors. However there’s extra to it than that, because the system frequently improves the inspection course of. If earlier than you had, say, 10 AOI defects together with 8 false calls and a pair of actual defects, the system may mechanically scale back that to only 2 defects for evaluate. So, as it really works within the background, it’s bettering the robustness of the inspection mannequin itself.

It’s nice {that a} buyer doesn’t have to study information science to know how deep studying does its job, however how do they know they will belief it to make the appropriate calls?

Nicolas: This can be a tremendous essential level, and there are primarily two solutions to that. The primary is that the system is educated on the client’s personal historic manufacturing information, their very own pictures and their very own sanctions. So, it’s solely the producer’s personal tolerances that enter into the system, that means there’s no threat of introducing new escapes. The second is that the annotation and neural community coaching steps are designed to present customers an understanding of the impression of their inspection mannequin — it’s like peeking contained in the field. The interface is tremendous easy to make use of, it helps you to simply group related pictures to search out any issues and validate all of the others in a single click on. A half-hour of coaching is sufficient, after which every little thing else — the info storage, importing, changing, and so on. — are all automated.

AOI inspection course of with DeepReview.

And what about information safety? That is fairly delicate data to place into the palms of an AI…

Romain: Because the server is on-premises, working in a closed system on the client’s personal sub-network, all information assortment, storage, coaching and processing are executed regionally. The shopper controls every little thing. It’s their very own neural community, their very own AI server.

Lastly, for many who’ve heard loads of guarantees about AI not too long ago, precisely what sorts of options can DeepReview acknowledge? And what are its limitations?

Romain: I completely agree that it’s essential to separate the fact from all of the hype that’s on the market round AI. It’s essential to remain practical. With DeepReview at this time, every little thing that may be seen in 2D colour imaging on smaller elements — broken, rotated, tilted or misaligned elements, or unhealthy solder joints, for instance — can all be processed. And extra capabilities — like the power to investigate every lead of a QFP or greater part — are coming quickly.

Nicolas: The restrictions have extra to do with the boundaries of picture classification usually — the truth that even probably the most superior AI fashions on this planet battle with classifying complicated patterns in 3D — fairly than the boundaries of our explicit system. However AI is evolving so quick that even it will change. And that’s one of many benefits of the annotation course of inside DeepReview: Every little thing a buyer does is successfully tagging the photographs in a approach that’s designed for the AOI to know. So there are loads of potential advantages even for the pick-and-place, solder paste Jet Printer and SPI sooner or later. Which means that when new duties come up, our clients shall be prepared. And every little thing shall be a lot simpler with a whole library, absolutely annotated and sanctioned by the individuals who know greatest: the PCB producers themselves.

DeepReview AI-guided labelling and coaching interface.

This articles is written by : Nermeen Nabil Khear Abdelmalak

All rights reserved to : USAGOLDMIES . www.usagoldmines.com

You can Enjoy surfing our website categories and read more content in many fields you may like .

Why USAGoldMines ?

USAGoldMines is a comprehensive website offering the latest in financial, crypto, and technical news. With specialized sections for each category, it provides readers with up-to-date market insights, investment trends, and technological advancements, making it a valuable resource for investors and enthusiasts in the fast-paced financial world.